The self-lubricating layer.

KANIFLON®

What is KANIFLON®?

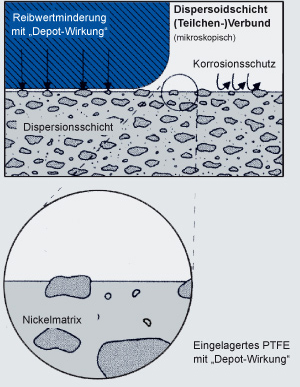

KANIFLON® is an internationally renowned brand name for a chemically precipitated nickel dispersion coat. By dispersion layer is meant a uniformly distributed incorporation of minute, non-metallic particles in the KANIGEN® matrix.

In KANIFLON®, additional unique properties are added to the excellent properties of the KANIGEN® base by the incorporation of about 20 vol.% PTFE.

Our technique guarantees uniform layer thicknesses even in strongly structured surfaces. Reproducible quality is another essential factor of our KANIFLON® technology.

Total properties:

- Chemical resistance

- Reduced coefficient of friction

- Hydrophobic properties offer problem solutions in lubrication, friction, adhesion, wear and corrosion in almost all industrial sectors.

With KANIFLON®, you have a sophisticated system adapted to the current demand for innovative surface technology. Because, KANIFLON® is always in the process of advanced development spending tremendous time and effort.

With KANIFLON®, you are using the chemically precipitated nickel-PTFE layer with the longest experience worldwide.

The advantages

Cost reduction

- Enables the use of low-quality base material

- Simplifies production, particularly in the area of chipping

- Offers optimum material combination possibilities

- Enables the recovery of the target state

- A uniformity and accuracy of layer up to ±2 % saves reworking

- High availability in terms of scarce resources

Quality enhancement

- Coating quality reproducible at the same level

- Competitive advantages by the increase in product quality

- High dimension accuracy of the KANIFLON® layer up to ±2 %

- Product features are positively modified

- Reduces adhesion through its hydrophobic property

- Significantly reduces static friction

- Protects against "seizing" due to lubricant failure

- Protects against corrosion and pollution

- Arrests wear of the carrier material

- Offers excellent dry operation properties

Excellent long-term properties

The incorporated PTFE particles by its "depot" effect guarantee a 100% functionality of the layer till its complete removal.

The features

Corrosion behaviour

As dispersion layer for specific application areas with problems of friction, adhesion and wear, KANIFLON® additionally offers an excellent corrosion protection. The attained test values are comparable with the values of our KANIGEN® method. By the incorporated PTFE, the values are consistently favourable.

Coefficients of friction

The low coefficient of friction of KANIFLON® is required if:

- Moving parts should guarantee their functions even after long downtimes

- Guidances, connections, joints, hinges, pistons, etc., rattle, jam, squeak, or tend to similarly undesirable occurrences

- The run-in period of components should be completed under easier, optimum conditions

- Lubrication systems are too expensive, too delicate, too maintenance-intensive, or not at all possible

- Lubrication systems have failed

Layer thickness

- Constant tolerance till ±2 %

- Maximum limit 25 μm in layer combination with KANIGEN® ∞

Operating temperature

Max. 250 °C in application

Hardness

- In deposition state about 300 – 350 HV 0.05

- After heat treatment about 290 °C about 400 – 450 HV 0.05

Specific weight

About 7.85 g/cm³

Adhesive strength

Up to 440 N/mm² depending on base material

Composition and effect

Diagram of the multi-level structure and effect of the dispersion layer KANISIL®.

Our obtained practical values correspond to the general state of the technology and the specifications of DIN EN ISO 4527.

Download & help

If you have questions, suggestions or requests? Then contact us equal. We are glad to be here for you.

Sonja Beisler

- Sales Assistant -

Phone: +49 6021 709-0

E-Mail: info@schnarr.eu

Our office hours are:

Mon - Thu: 8:00am - 4:00pm

Fri: 8:00am - 1:30pm